|

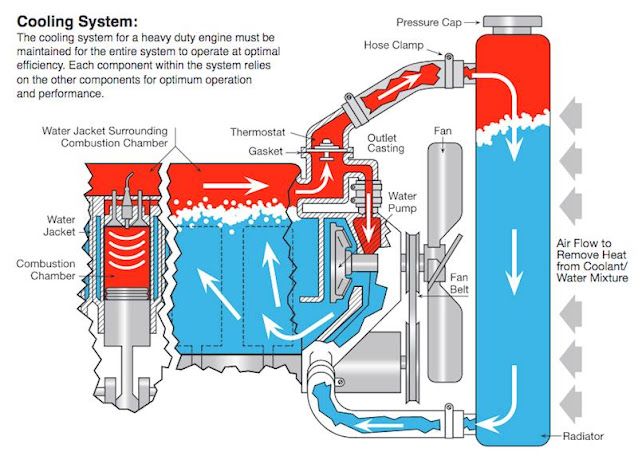

| Fig: Freeze protection pro cooling system diagram |

The freeze protection pro cooling system

Solidifying or Freezing is one of the most imperative vocabularies in the cooling framework; because of solidifying in the cooling framework liquid stream is blocked, metallic channels broke, supplies cracked and so on, and trouble happened. To keep nonstop sheltered and sound fluid stream solidify assurance then again against solidifying framework is required both in re-flowed water framework and shut-circuit liquid cooler framework.

Freeze protection for re-circulating water system:

The least difficult and best method for keeping the re-flowed water from solidifying is to utilize a remote sump. With a remote sump, the re-coursing water pump is mounted remotely at the sump and at whatever point the pump is closed off, all re-flowing water channels back to the sump.

Sponsored:

Sponsored:

In the event that a remote sump can't be utilized, dish radiators are accessible. Either electric radiators, boiling point water loops, steam curls, or steam injectors might be utilized to warm the bowl water when the unit is closed down. Nonetheless, the bowl radiator won't keep the outer water lines, pump or pump channeling from solidifying. The make-up water supply, flood and deplete lines, and additionally the pump and pump speaking up to the flood level must be warm followed and protected to shield them from harm.

A condenser or cooler can't be worked dry (fans on, pump off) unless the water is totally depleted from the container. The container warmers are measured to keep skillet water from solidifying just when the unit is totally closed down.

Freeze Protection of Closed Circuit Fluid Cooler Coils:

Utilizing a repressed ethylene glycol liquid catalyst is the least complicated and best method for shielding the warmth exchanger curl from solidifying. In the event that this is impractical, an assistant warmth load must be kept up on the curl at all times so that the water temperature does not drop below 50F when the cooler is closed down. A base prescribed stream rate should likewise be kept up.

Sponsored:

Sponsored:

On the off chance that a radiator fluid arrangement is not utilized, the loop must be depleted promptly at whatever point the pumps are closed down or the stream stops. This is expert via programmed channel valves and air vents in the funneling to and from the cooler. Care must be taken to guarantee that the channeling is enough protected and estimated to permit the water to stream rapidly from the loop. This strategy for assurance ought to be utilized just as a part of crisis circumstances and is neither a functional nor prescribed technique for stopping insurance. Curls ought not to be depleted for a developed timeframe.

At the point when the unit is in operation amid solidifying climate, some sort of limit control is ordinarily required to keep water temperatures from dropping below 50F. Working dry with a remote sump is an amazing method for diminishing unit limits at low temperatures. Different strategies for limit control incorporate two velocity engines, VFDs, Fan cycling, and fan dampers (on constrained Draft units as it were). These can be utilized separately or as a part of a blend with dry/Remote sump operation.

Sponsored:

Sponsored:

Trust this article on stop security framework ace cooling framework will help you to run the cooling plant and recoup the framework in the blink of an eye if down the framework due to solidifying.

Utterly written written content, Really enjoyed examining.

ReplyDeleteI was looking for keyword and came across this post. The least difficult and best method for keeping the re-flowed water from solidifying is to utilize a remote sump. This is well written and describe in detail. Thanks for sharing this.

ReplyDeleteWe are grateful that you have such high-quality information on your blog.Abogado de Conducción Imprudente Condado de Morris.||Abogado de Conducción Imprudente del Condado de Morris.

ReplyDelete