| Air-Side Economizer Flow Diagram |

Economizer Working Principle in Centrifugal Chiller System

Air-side economizer to save energy in a building

A building's HVAC system can make use of an air-side economizer to save energy in buildings by using cool outside air as a means of cooling the indoor space.

When the temperature of the outside air is less than the temperature of the re-circulated air, conditioning with the outside air is more energy-efficient than conditioning with re-circulated air.

When the outside air is both sufficiently cool and sufficiently dry (depending on the climate) the amount of enthalpy in the air is acceptable and no additional conditioning of it is needed; this portion of the air-side economizer control scheme is called free cooling.

With the appropriate controls, economizers can be used in climates which experience various weather systems.

water-side economizer to save the energy:

Air-side economizers can reduce HVAC energy costs in cold and temperate climates while also potentially improving indoor air quality but are most often not appropriate in hot and humid climates.

When the outside air's dry- and wet-bulb temperatures are low enough, a water-side economizer can use water-cooled by a wet cooling tower or a dry cooler (also called a fluid cooler) to cool buildings without operating a chiller.

They are historically known as the strainer cycle, but the water-side economizer is not a true thermodynamic cycle. Also, instead of passing the cooling tower water through a strainer and then to the cooling coils, which causes fouling, more often a plate-and-frame heat exchanger is inserted between the cooling tower and chilled water loops.

They are historically known as the strainer cycle, but the water-side economizer is not a true thermodynamic cycle. Also, instead of passing the cooling tower water through a strainer and then to the cooling coils, which causes fouling, more often a plate-and-frame heat exchanger is inserted between the cooling tower and chilled water loops.

Using Economizer in Centrifugal Chiller HVAC System

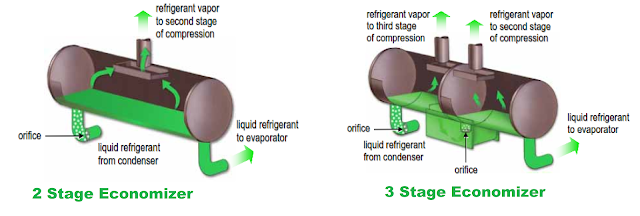

The figure shows how the economizer works in the centrifugal chiller for 2 2-stage chiller and a 3-stage chiller.

An economizer can be used in conjunction with multiple expansion devices to improve the efficiency of a multi-stage chiller. In a chiller with a 2-stage compressor, the expansion process can be separated into 2 steps with an economizer chamber between.

An economizer can be used in conjunction with multiple expansion devices to improve the efficiency of a multi-stage chiller. In a chiller with a 2-stage compressor, the expansion process can be separated into 2 steps with an economizer chamber between.

Read unlimited PDF books on HVAC

Liquid refrigerant from the condenser enters the first expansion device, which reduces the pressure of the refrigerant to that of the second-stage impeller inlet.

This pressure drop causes a portion of the liquid refrigerant to evaporate, or flash and the resulting mixture of liquid and vapor enters the economizer chamber.

Here, the vapor is separated from the mixture and is routed directly to the inlet of the second-stage impeller.

This pressure drop causes a portion of the liquid refrigerant to evaporate, or flash and the resulting mixture of liquid and vapor enters the economizer chamber.

Here, the vapor is separated from the mixture and is routed directly to the inlet of the second-stage impeller.

The remaining liquid travels onto the second expansion device and evaporator.

The benefit of the economizer will be discussed in greater detail in Period 2. In a chiller with a 3-stage compressor, the expansion process can be separated into 3 steps with separate economizer chambers between the steps.

This pressure drop causes a portion of the liquid refrigerant to flash, and the resulting mixture of liquid and vapour enters the high-pressure chamber of the economizer.

Here, the vapor is separated from the mixture and is then routed directly to the inlet of the third-stage impeller. The remaining liquid travels onto the second expansion device.

This pressure drop causes a portion of the liquid refrigerant to flash, and the resulting mixture of liquid and vapor enters the low-pressure chamber of the economizer.

Here, the vapor is separated from the mixture and routed directly to the inlet of the second-stage impeller. The remaining liquid travels onto the third expansion device and evaporator.

Just before entering the evaporator, the liquid refrigerant flows through a second expansion device that reduces its pressure and temperature to evaporator conditions.

Flashing a portion of the refrigerant prior to the economizer reduces the amount of compressor power required since the refrigerant vapour generated in the economizer only needs to be compressed by the second-stage impeller.

Liquid refrigerant from the condenser enters the first orifice (expansion device), which reduces the pressure of the refrigerant to that of the third-stage impeller inlet.

The second expansion device further reduces the pressure of the refrigerant to that of the second-stage impeller inlet.

Hope it will help with the basic understanding of 2-stage chiller and 3-stage chiller economizer.

Reference: Trane Chiller

ReplyDeleteWe manufacture wide range of PVC Eliminator, PVC Nozzles and hollow frp fans. We make all types of cooling towers that fulfil the requirements of our innumerable clients.

PVC Eliminator manufacturers

PVC Nozzles manufacturers

Hollow frp fans manufacture

FRP Cooling Tower

Water cooling towers manufacturers

Cooling tower manufacturers in India

Wooden cooling tower manufacturers

Timber Cooling Tower manufacturers

ReplyDeleteWe manufacture wide range of PVC Eliminator, PVC Nozzles and hollow frp fans. We make all types of cooling towers that fulfil the requirements of our innumerable clients.

PVC Eliminator manufacturers

PVC Nozzles manufacturers

Hollow frp fans manufacture

FRP Cooling Tower

Water cooling towers manufacturers

Cooling tower manufacturers in India

Wooden cooling tower manufacturers

Timber Cooling Tower manufacturers

Hi guys ! You are welcome to write any engineering or technical article in this blog .

ReplyDeleteJust desire to say your article is as astounding.

ReplyDeleteThe clarity in your publish is simply spectacular and that i can assume you are knowledgeable in this subject.

Fine together with your permission allow me to take hold of your feed to stay updated with approaching post.

Thank you 1,000,000 and please carry on the gratifying work.

Great Article! I got too much information from this post. Thanks for sharing such a helpful article. Click here to more information about it

ReplyDeleteGreat Article! Mobile Phones Price Bd

ReplyDeleteشركة كشف تسربات المياه بالقطيف

ReplyDeleteشركة مكافحة حشرات بالقطيف

شركة تسليك مجاري بالقطيف

شركة عزل اسطح بالقطيف

شركة لمسات الابداع

شركة ركن كلين للخدمات المنزلية

ReplyDeleteشركة مكافحة حشرات شمال الرياض

شركة مكافحة حشرات شرق الرياض

شركة مكافحة حشرات غرب الرياض

شركة مكافحة حشرات جنوب الرياض

_____________

شركة رش مبيدات شمال الرياض

شركة رش مبيدات شرق الرياض

شركة رش مبيدات غرب الرياض

شركة رش مبيدات جنوب الرياض